Empty Container Placement Optimization

Objective

Design a solution that alleviates the challenges associated with container placements, namely

- Reduce transportation cost of repositioning

- Maximize system revenue generating potential

- Determine inventory levels for strategic hubs

- Balance buy/lease new vs. repair/maintenance

Industry: Healthcare-Wholesaler

Services: Technology Innovation

Technology: Mathematical Optimization

Reduction of

10%

in average placement transportation costs

Reduction of

33%

in the number of daily Cocoon placement moves for the weekdays

Reduction of

25%

in overall operating cost

Our Client

Is a Fortune 100 global healthcare wholesaler and one of the largest drug distributor in the U.S., supplying a wide range of pharmaceuticals, as well as medical supplies and equipment.

Challenge

Empty container repositioning is one of the most critical issues facing the supply chain, due to the unbalanced nature of import-export traffic. Shortfall of containers at origins is detrimental to logistics providers. The cost to return containers, service/ maintenance non-availability of existing containers, repurposing different container sizes or acquiring new containers to serve revenue opportunities are among the tradeoffs to be considered in the empty container repositioning puzzle.

Approach

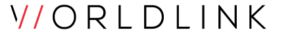

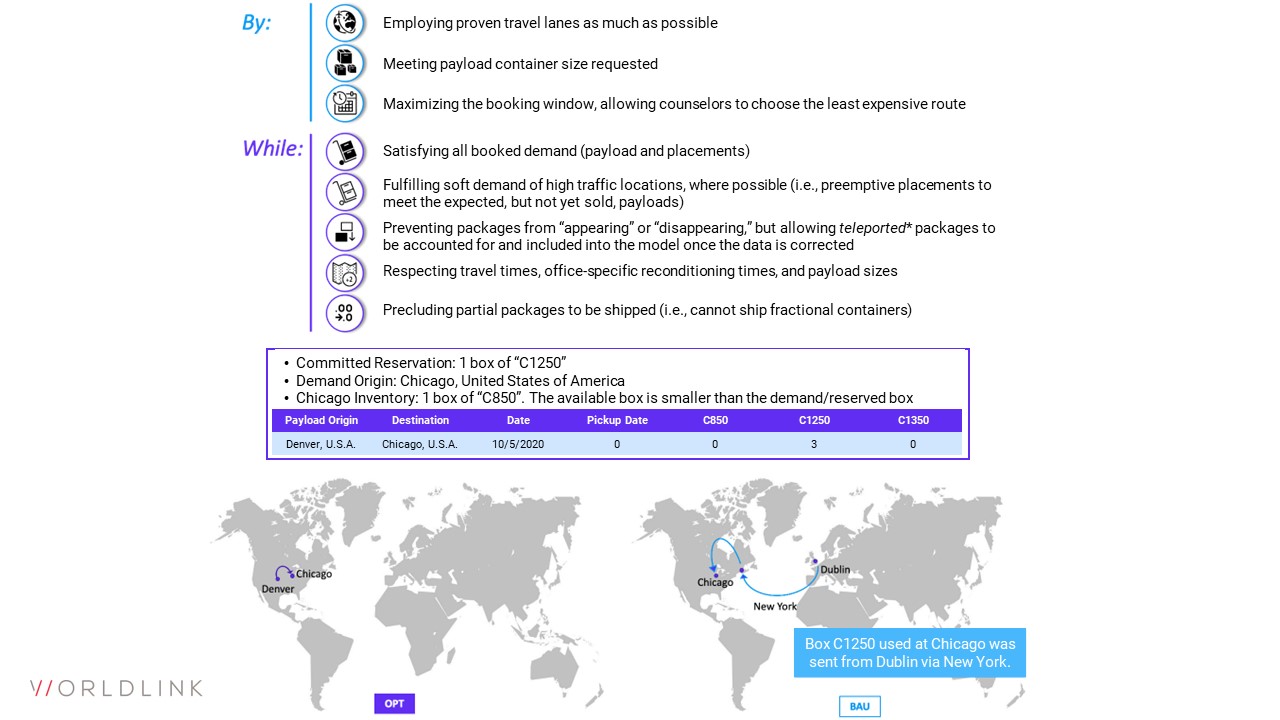

A comprehensive Advanced Analytics solution that:

- Leverages a comprehensive repository of relevant internal and external data

- Improved visibility into expected demand

- Optimized containers repositioning based on the forecasted demands

Outcomes

- Automated the inefficient and labor-intensive repositioning of containers

- Designed opportunistic container inventory policies at strategic hubs, to minimize the need for intercontinental container repositioning

- Maximized payload utilization of containers

- Increased revenue based on eliminating missed opportunity due to container limitations

- Improved customer satisfaction and loyalty due to fewer late delivery incidents

Impact

- ~ 33%+ reduction in the number of daily Cocoon placement moves for the weekdays

- 10%+ reduction in average placement transportation costs

- Multiplicative effect of the reduced placement moves and lower transportation costs, results in a compelling overall operating cost reduction of 25%

- Increased container utilization and revenue potential due to better supply vs. demand visibility

- Recognized inventory policies at strategic hubs to minimize the need for cross-continental transportation

View more Case Studies

Issues (Risk) Correlation & Consolidation Analysis

Hybrid Cloud Analytics

Data Strategy Implementation

Ready to transform your business?

Explore Our Services and Unleash Your Potential Today!